Lime Sludge Centrifudge Package

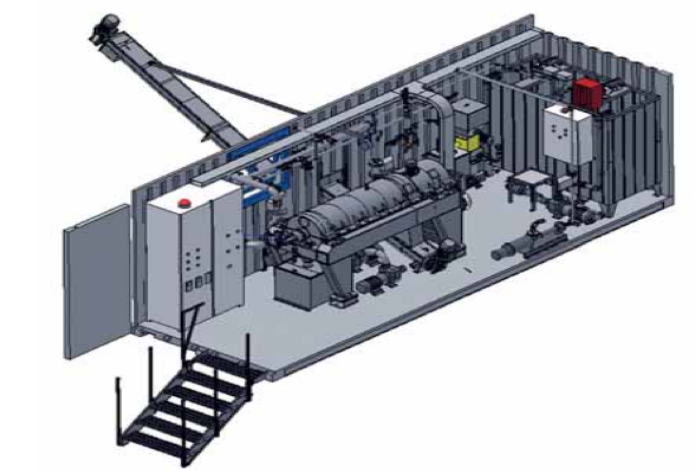

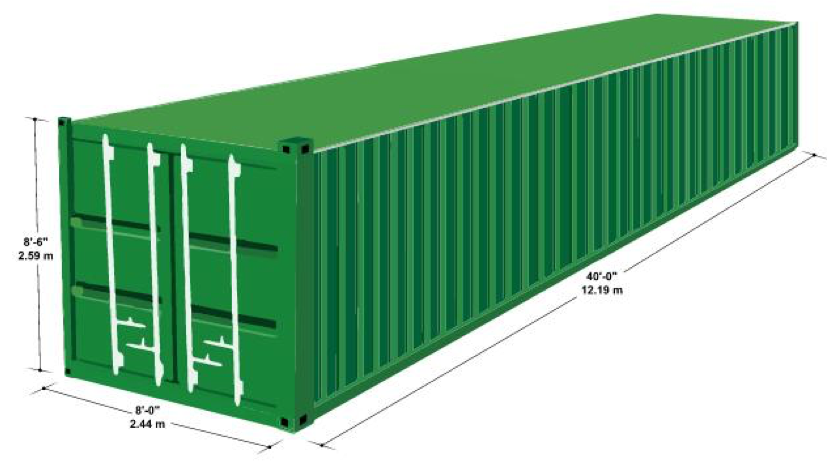

The COOEC Lime Sludge Handling System is the first full modular system to be deployed in the SAGD industry. The system consists of 4 modules, each of which is installed inside a standard ISO shipping container (8 ft x 8.5 ft x 40 ft), which renders the system easy to transport, assemble and operate. The key functions of the system include chemical dosing, decanter centrifuge, centrate dewatered sludge collection, as well as solid storage. The entire system is controlled by a dedicated Programmable Logic Controller (PLC) that interfaces and integrates with client’s Distributed Control System (DCS) using modern industrial communication protocols. When the feeding condition changes, the system will adjust the operation parameters accordingly, making it completely automatic without the need for operator interference. Due to the compact design and full automation, both the capital and operation cost are significantly reduced – one of our current clients has estimated that their calculated payback time is less than three years.

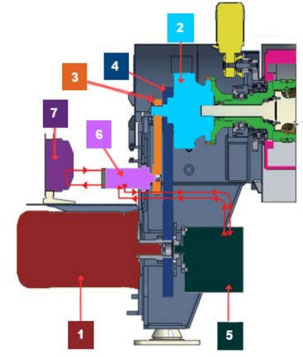

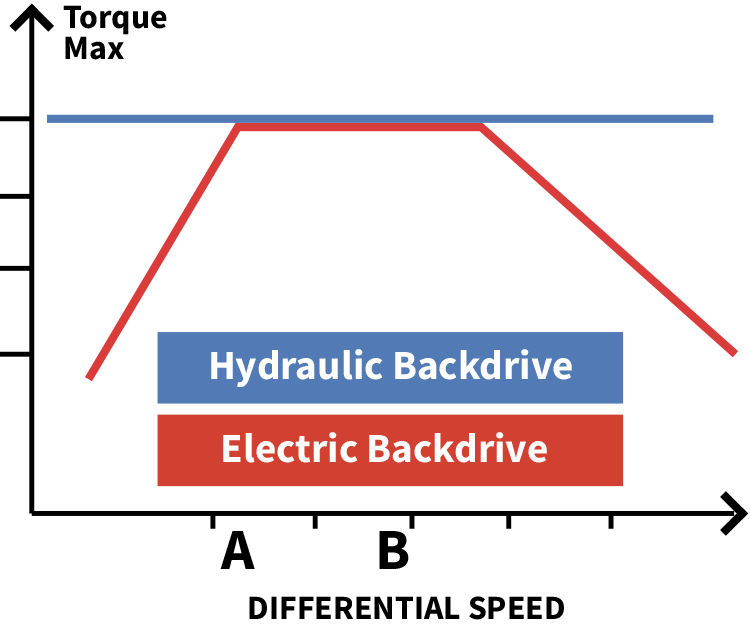

Hybrid Electro Hydraulic Transmission

-

Main Motor

-

Gearbox

-

Scroll Belt

-

Bowl Belt

-

Variable Flow Hydraulic Pump

-

Hydraulic Motor

-

Fan-Cooled Heat Exchanger

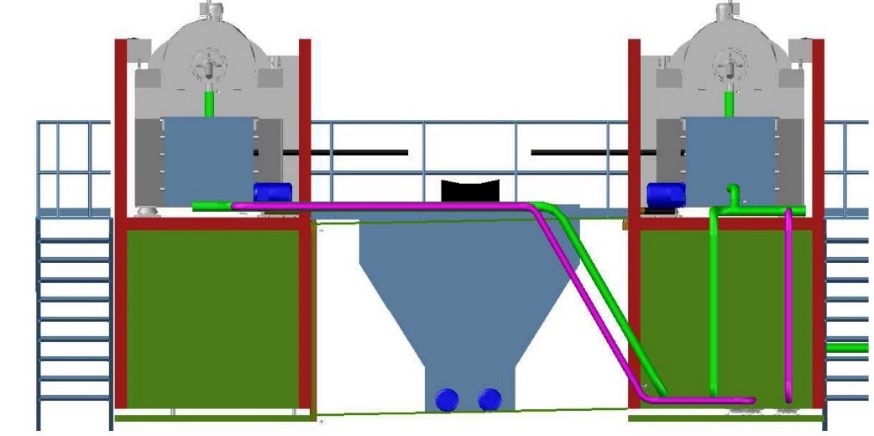

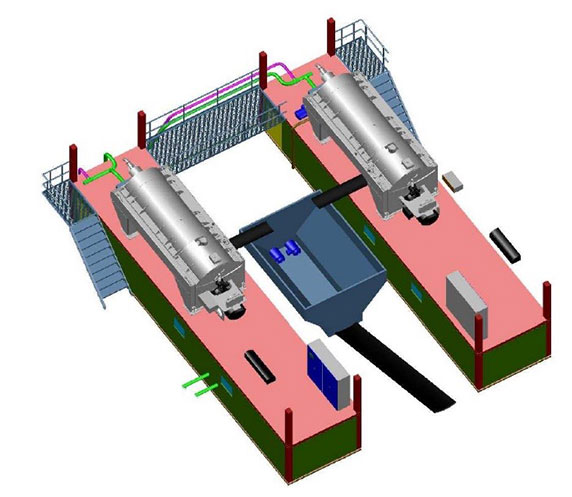

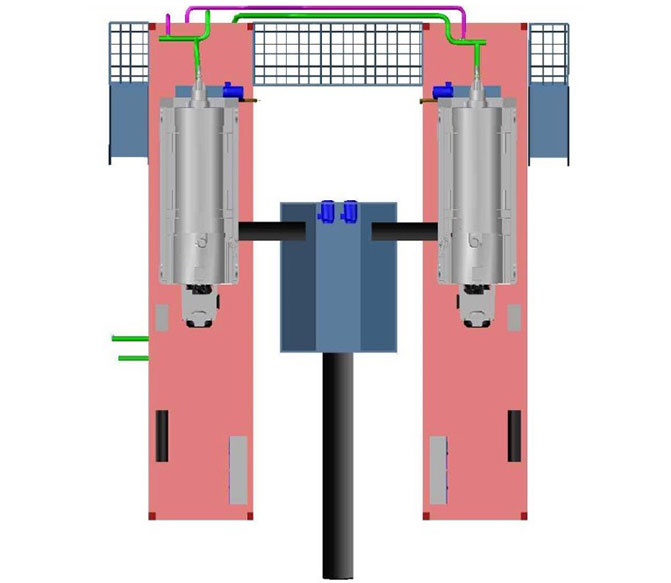

Modular Design

-

4 standard sea containers (40′ x 8′ x 8’6”)

-

R20 insulated for -40°C to 30°C

-

HVAC system installed

Optional

-

Solid bin with screw conveyer

-

Saw dust hopper

-

Saw dust screw conveyer

Container |

Equipment |

Total weight (kg) |

|---|---|---|

| Container 1 | Polymer dosing + centrate handling | 5, 100 |

| Container 2 | Centrifudge 1 | 19, 550 |

| Container 3 | Pumps + centrate handling | 7, 140 |

| Container 4 | Centrifuge 2 | 19, 550 |

Package 3D Models